What is Flexible and Expandable Conveyor?

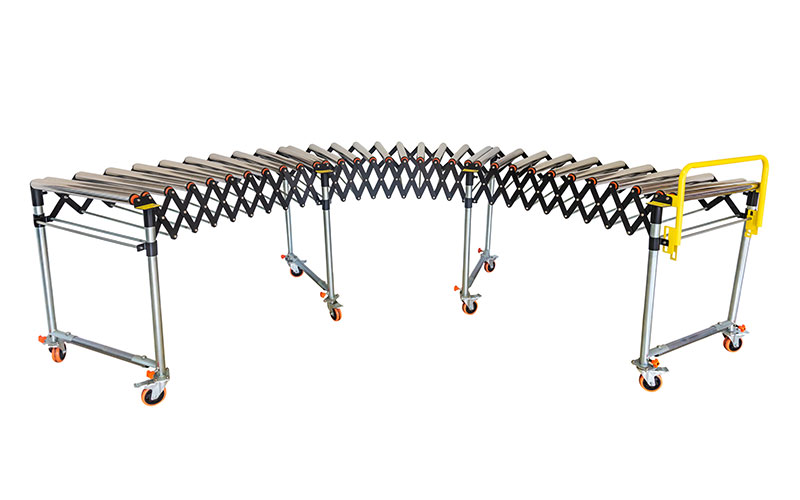

The flexible conveyor is a flexible and expandable conveyor that can be stretched, shortened, and bent, which transports the item from the point t A o the point B along the custom path. Frames of flexible conveyors are equipped with wheels that can be easily moved to anywhere. It can be used to easily and quickly create a highly efficient cargo transportation system for many temporary needs, suitable for unloading, loading, temporary transportation, and reception of goods.

Structure of Flexible and Expandable Conveyor

Flexible conveyors usually consist of rollers, skate wheels, support legs, motors, driving belts, blocking blocks, handles, etc.

The supporting leg is designed as a structure that can be extended and shortened, so that by setting multiple different lengths of supporting legs, an inclined transmission surface can be obtained.

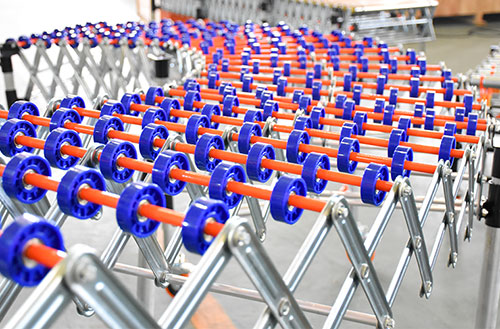

The transmission surface of the flexible conveyor is composed of many rollers or skate wheels. Adjacent rollers or skate wheels are connected by two fixed connecting rods that cross each other. The rollers are installed at the same end of the connecting rod, and the other end of the connecting rod is connected by a shaft. In this way, an X-shaped structure is formed, which can perform scissors-like movement when stretched and shortened by force.

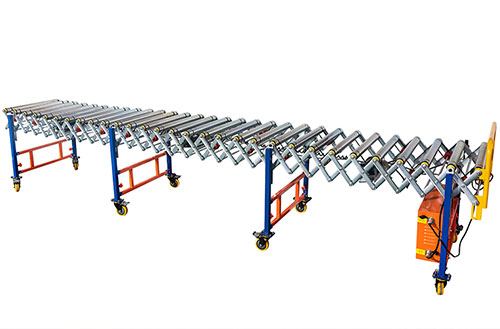

The powered flexible conveyor is equipped with a motor and a drive belt, and the drive belt is wound on two adjacent rollers. Then install a motor at a position of the flexible conveyor, and use the motor to drive the belt to move, thereby driving the roller to rotate to transport the object.

Principle of Flexible and Expandable Conveyor

Different from other conveyors, the flexible conveyor is a kind of conveyor that can be stretched and shortened for conveying objects. Its surface is composed of rollers or skate wheels to form a plane to transport objects. There are many support legs with casters, and each support leg is connected by several crossed and flexible scissors-like rods. When the distance between the supporting legs is changed by force, these crossed rods are driven to make a scissors-like movement, the distance between the rollers fixed on the ends of the crossed rods will be extended or shortened, thereby realizing the telescopic function of the flexible conveyor.

The rollers and skate wheels of the gravity flexible conveyor have no external driving power. By adjusting the height of the two ends of the flexible conveyor, the flexible conveyor forms an inclined plane. The object is being transported slides in a lower direction through freely rollers or skate wheels on this inclined transmission plane due to its own gravity.

A springy rubber belt is wound between each roller of the power flexible conveyor. The motor drives the rubber belt to drive the roller to rotate to convey objects.

Types of Flexible and Expandable Conveyor

Different flexible conveyors have many differences, but they can be divided into main types according to their driving force and the material of the transport surface.

According to the power used by the flexible conveyor to transport goods, we can divide it into a gravity flexible conveyor and a power flexible conveyor.

Gravity flexible conveyor is a kind of flexible conveyor that slides goods on the conveying slope due to its own gravity. On the gravity flexible conveyor, the forward direction of the goods can only move from the higher end to the lower end. It cannot move the goods to a higher position. Even on the same horizontal plane, the goods will not move without driving force.

The power flexible conveyor is a flexible conveyor that is driven by a motor to generate power to transport goods. The power flexible conveyor, driven by the motor, can transport the goods to a higher or lower position. Or it can be freely controlled on the same level to move the goods forward or backward.

According to the different transportation surface materials, we can divide flexible conveyors into roller flexible conveyors and skate wheels flexible conveyors. Roller conveyors are suitable for materials with flat or complex bottoms.

Why use Flexible and Expandable Conveyor

Flexible conveyors are a kind of temporary conveyors that have the ability to stretched and shortened, are very fast and flexible, and can move products easily and efficiently. They are compact in structure and occupy a small space.

For seasonal companies such as tourism, catering, and seasonal clothing, they have obvious peak and off-season production every year or every period of time, and they may not need large-scale permanent conveying systems that take up a lot of space. They need a more flexible, efficient, and inexpensive equipment that can meet their production efficiency during peak seasons and reduce unnecessary expenses during off-season. They need a cheap and temporary conveyor line. The flexible conveyor line is very suitable for this demand. It is not only light and flexible, but also can quickly improve production and handling efficiency. At the same time, it can be shrunk and stored when not in use, without taking up more production funds, ground and space.

In some situations that are not suitable for fixed conveyors, such as when trucks need to load and unload goods at different locations, these locations are not designed as long-term fixed loading and unloading points, so they will not be equipped with fixed conveyor lines. At this time, flexibility is very suitable for this situation, and even flexible conveyors can become conventional equipment on trucks, following the truck in different locations to efficiently complete loading and unloading operations.

Where is the Flexible and Expandable Conveyor used

Here is the flexible conveyor used

Different from other permanently built fixed conveyor lines, flexible conveyor lines are more suitable for the following places:

- Places with limited venues and space, or limited storage space. In some cities where land is very expensive, more companies tend to be miniaturized, and they cannot design some areas for a single permanent purpose. Therefore, fixed permanent transmission lines cannot be built-in these places. Moreover, after temporarily using the conveyor line, it needs to be stored and occupies a minimum space.

- The loading and unloading configuration is temporary and may change quickly. According to some temporary requirements, it is necessary to quickly and efficiently complete a batch of loading and unloading operations in places that were not originally designed for loading and unloading.

- Need multiple loading or unloading points,

- Loading and unloading speed is the key issue,

- Need to flexibly deal with fluctuations in different capacities. For some companies, they usually unload the goods by trucks, stack them on pallets, and then use forklifts to transfer the pallets to the warehouse one by one. However, occasionally when the amount of goods is huge, they need to quickly move the goods directly and at once. It is necessary to create a flexible conveyor line at the beginning of the truck unloading section to directly transport the goods to the store

Flexible conveyors are usually used at loading docks or at the end of another conveyor system to connect to trucks or vans. It is very suitable for truck and container loading and unloading, packaging, transportation and flexible assembly line applications. Suitable for small and medium batch transportation, packaging and assembly.

Advantages of Flexible and Expandable Conveyor

- Can be extended and shortened: The available extendable length can be easily adjusted, stretched to four times its length according to the area that needs to be covered, and can be easily folded when not in use

- Small space occupied: The conveyor system is very compact when not in use, and takes up very little space. They can be stored under the pallet rack or almost anywhere to save space and expand to meet your needs.

- Versatility: Whether you need a flexible power conveyor to move around corners, meet multiple docks, or where there are other infrastructure or equipment for close navigation, the power flexible conveyor can meet these requirements.

- High efficiency: In some places where there is no fixed permanent conveyor, the flexible conveyor can quickly form a temporary conveyor line, spend less time moving goods in and out, improve productivity and improve work efficiency.

- High safety: Reduce the circulation of goods between the two points of transmission, reduce the steps of stacking, palletizing, and handling goods, and improve the safety of goods. Reduce the risk of injury caused by manual handling.

- Flexible: Equipped with casters so that they can be easily rolled and stored without the use of a forklift. It can be moved and built by one person. Multiple flexible conveyors can be connected together to extend the conveying distance. Flexible conveyor expansion conveyor can squeeze into a narrow space, can transport a variety of different products.

- Arbitrary curved: The two sides of the flexible roller conveyor can be extended and contracted separately, so when one side extends and the other side contracts, the flexible roller conveyor can form a bending angle. After the flexible roller conveyor is bent, it can avoid obstacles in the work space and arrange an accurate and specific path according to a specific route.

- Self-tracking: The items conveyed on the flexible roller conveyor can follow the route of the flexible roller conveyor. When the flexible roller conveyor is bent, it can also follow the curved flexible roller conveyor through the corresponding curved route. Self-tracking, cartons follow the twists and turns of the conveyor path.

- Cheap: This self-tracking function keeps your load on the conveyor belt and avoids the use of other more expensive solutions. The flexible and expandable conveyor not only has many physical advantages, it is also a cheap alternative and will improve the overall condition of your transportation and receiving department

Their expansion and contraction capabilities provide a simple solution for mobile products that can be moved easily and efficiently.