What Is a Modular Workbench and Why Does Every Efficient Workspace Need One?

In an era where adaptability defines success in manufacturing and assembly, modular workbenches emerge as game-changers. What exactly makes them indispensable for modern operations?

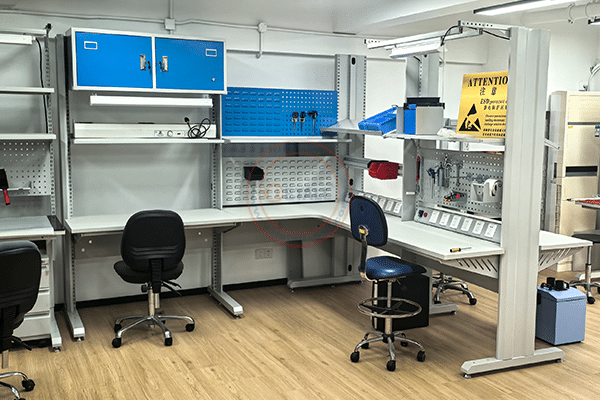

A modular workbench is a flexible, scalable workstation system built around interchangeable components for customized setups. It prioritizes space efficiency, cost savings, and rapid reconfiguration, ideal for dynamic environments like factories and labs.

Now modular workbenches continue to transform industries by enabling seamless expansions without downtime. This guide explores their core concepts and advantages, drawing from the latest innovations in workspace design.

Why Are Modular Workbenches Gaining Popularity?

Traditional fixed desks limit growth, but modular systems adapt effortlessly. Why are they trending now?

Modular workbenches are popular due to their adaptability in fast-evolving industries like e-commerce and tech manufacturing. They allow quick adjustments to workflow changes, reducing waste and enhancing productivity.

Drivers of Adoption

The surge in remote and hybrid manufacturing, as noted in a 2025 industry report, pushes demand for systems that scale with business needs, cutting setup times by up to 40%.

Economic Edge

One facility reported 25% cost reductions after switching, thanks to shared structural elements that minimize material use.

Sustainability Angle

The sustainability advantage lies in the modular design—components can be easily replaced or added without purchasing an entirely new system, reducing waste and extending product life.

What Are the Key Features of a High-Quality Modular Workbench?

Features distinguish superior models. What should one look for in a modular workbench?

Key features include perforated uprights, quick-hang accessories, and dual-sided configurations. These enable tool-free expansions and personalized stations.

Innovative Structures

Perforated columns replace bulky legs, allowing accessories like shelves or power outlets to hang effortlessly, creating independent zones between uprights.

Customization Capabilities

Users can add lighting, storage, or ergonomic aids. A 2025 survey showed 30% efficiency gains from such tailoring.

Durability Factors

Robust materials ensure longevity, with some models supporting back-to-back setups for high-density layouts.

How Do Modular Workbenches Optimize Space and Costs?

Space and budget constraints challenge many operations. How do modular workbenches solve this?

Modular workbenches optimize space by eliminating traditional supports and enabling dense configurations, while cutting costs through scalable designs. Shared uprights reduce per-station expenses as setups grow.

Space-Saving Mechanics

Dual-sided uprights double workstation capacity in the same footprint, perfect for cramped warehouses.

Cost Breakdown

Initial investments pay off quickly; adding uprights creates multiple stations at fractional costs, with averages dropping 40% in large installations.

Comparison Table

| Aspect | Traditional Bench | Modular Workbench | Savings Potential |

|---|---|---|---|

| Space Usage | High | Low | Up to 50% more density |

| Expansion Cost | Expensive | Economical | 30-45% lower |

| Setup Time | Lengthy | Quick | 40% faster |

What Industries Benefit Most from Modular Workbenches?

Versatility makes them adaptable. Which sectors see the greatest impact?

Industries like assembly, research, and logistics benefit most from modular workbenches. Their scalability suits high-variability tasks.

Assembly and Manufacturing

Streamlined lines with quick-reconfigure options boost throughput by 25% in automotive plants.

Laboratories and Workshops

Custom accessories for tools and samples enhance precision.

Packing and Shipping

Efficient stations reduce errors in e-commerce fulfillment, handling peak demands seamlessly.

How to Set Up and Maintain a Modular Workbench System?

Implementation is key to success. How does one install and upkeep these systems?

Setting up involves anchoring uprights, adding tabletops, and configuring accessories; maintenance requires regular inspections. This ensures long-term performance.

Installation Steps

- Mount the base upright.

- Connect extensions for desired length.

- Attach tops and hang-ons.

- Test stability.

Maintenance Best Practices

Clean surfaces monthly and check connections quarterly. A Hong Kong warehouse extended system life by 30% with routine care.

What Are the Future Trends in Modular Workbench Design?

Innovation never stops. What lies ahead for modular workbenches?

Future trends include AI integration, sustainable materials, and enhanced ergonomics. These will redefine workspace adaptability.

AI and Automation

Predictive layouts via AI optimize configurations, potentially increasing efficiency by 35%.

Ergonomic Advances

Height-adjustable features with health monitoring will prioritize worker well-being.

Conclusion

A modular workbench revolutionizes workspaces through scalability, efficiency, and customization. From key features and space optimization to industry applications, setup, and future trends, these systems offer unmatched value. As of November 28, 2025, embracing modular designs positions businesses for sustained growth in competitive markets.