What is an ESD Workbench?

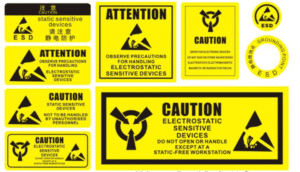

An ESD workbench, or Electrostatic Discharge workbench, is a specialized workspace designed to prevent damage from electrostatic discharge (ESD) to sensitive electronic components. Static electricity poses a significant threat to electronics, with even a tiny spark capable of causing substantial damage. An ESD workbench effectively prevents the formation of static electricity and safely discharges it, ensuring a safe working environment for handling and repairing electronic devices.

Key Features of an ESD Workbench

1. Static-Dissipative Surface

The core component of an ESD workbench is its static-dissipative surface, typically made from materials such as laminate, rubber, PVC, vinyl mat, or special polymers. This surface helps to discharge static electricity to the ground, protecting sensitive components from damage.

2. Grounding System

ESD workbenches are equipped with a reliable grounding system. This includes a central receptacle for connecting ground points from ESD floor mats, wrist straps, and other ESD accessories, ensuring a zero-potential ground between the floor/earth, the worksurface, and the user.

3. Modular Add-Ons and Durability

These workbenches often feature modular add-ons like heat-resistant surfaces, which are ideal for hand assembly lines. The materials used are durable, capable of resisting heat, chemicals, and wear, making them suitable for a variety of industrial applications.

Importance of ESD Table Tops

An ESD table top is crucial for any ESD workstation. Unlike regular tables where static easily builds up and can damage sensitive devices, an ESD table top uses static-dissipative materials to safely discharge static electricity to the ground. This prevents harm to sensitive components during handling and repair processes.

Comparison with Anti-Static Mats

While anti-static mats are a common solution, they are not as comprehensive as an ESD laminated top. Here's a comparison:

| Feature | ESD Laminated Top | Anti-Static Mat (Typical) |

|---|---|---|

| Material | Static-dissipative laminate | Rubber or PVC |

| Durability | Resists heat, chemicals, wear | Easily damaged by soldering |

| Grounding | Integrated, multiple points | Single wire, prone to failure |

| Static Control | Consistent across entire surface | Limited to mat area, wire dependent |

Anti-static mats, often made of rubber or PVC, can degrade quickly and are susceptible to damage from hot soldering irons. Moreover, their single grounding wire can fail unnoticed, rendering the mat ineffective.

Requirements for an ESD Bench

To be effective, an ESD bench must meet stringent standards set by organizations like IEC and ANSI. Key requirements include:

- Static-Dissipative Surface: The surface resistance should be between 10^4 and 10^9 ohms, ensuring proper charge dissipation without posing a shock hazard.

- Reliable Grounding System: A common point ground connects all elements (surface, wrist straps, etc.) to earth, with ground wires having low resistance (typically < 1 ohm) for fast static discharge.

- Material Properties: The bench must withstand solvents, fluxes, and cleaners used in electronics work, as well as resist heat from soldering applications and mechanical wear from tools and components.

- Ergonomics: Adjustable height and comfortable design ensure user safety and efficiency.

Applications and Benefits

ESD workbenches are essential in industries where the handling of sensitive electronic components is frequent, such as flat-panel, medical device, printed circuit board, and semiconductor manufacturing. They provide a safe working environment by evenly distributing electron charges and uniformly neutralizing excess charges, thereby preventing ESD events that could lead to device failure.

Conclusion

An ESD workbench is more than just a table with a special mat; it's a complete system designed to control static electricity. By combining conductive materials, secure grounding, and robust construction, ESD workbenches offer a comprehensive solution for protecting sensitive electronics from the dangers of electrostatic discharge. Whether in a compact table format or a full workbench setup, investing in an ESD workbench ensures the safety and reliability of your electronic components.