Understanding ESD Symbols: Meanings, Applications, and Best Practices

Static electricity can silently damage sensitive electronics, costing thousands in losses. Are you using the right ESD symbols to protect your workspace?

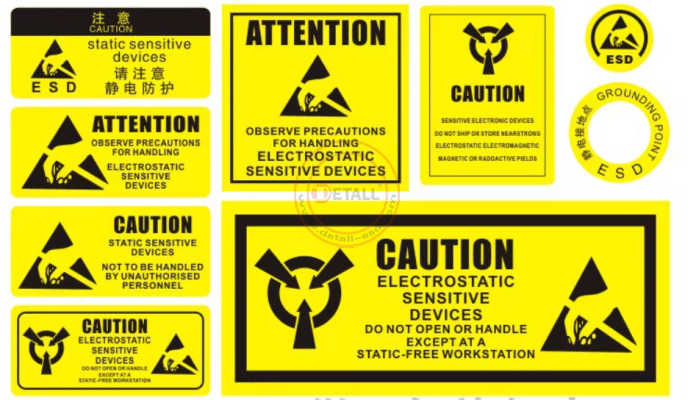

ESD symbols guide safe handling of electronics. They include the Susceptibility Symbol (warning of ESD-sensitive items), Protective Symbol (indicating ESD-safe products), and Common Point Ground Symbol (marking grounding points).

What Are ESD Symbols and Why Do They Matter?

Static shocks can ruin delicate circuits. Are you confident your team recognizes ESD risks?

ESD symbols are visual cues for electrostatic discharge protection. They mark sensitive components, protective gear, and grounding points, ensuring safe handling in electronics workspaces.

Role in Electronics Safety

ESD symbols alert workers to risks and guide proper handling. Clear symbols prevent such errors.

Types of Symbols

Three main symbols are used: Susceptibility, Protective, and Common Point Ground. Each has a distinct design and purpose, standardized for global recognition.

Practical Impact

Using these symbols correctly reduces failures.Aligning with ANSI/ESD S8.1.

The ESD Susceptibility Symbol: Warning of Sensitive Components

Unmarked components can lead to accidental damage. Are your sensitive electronics properly labeled?

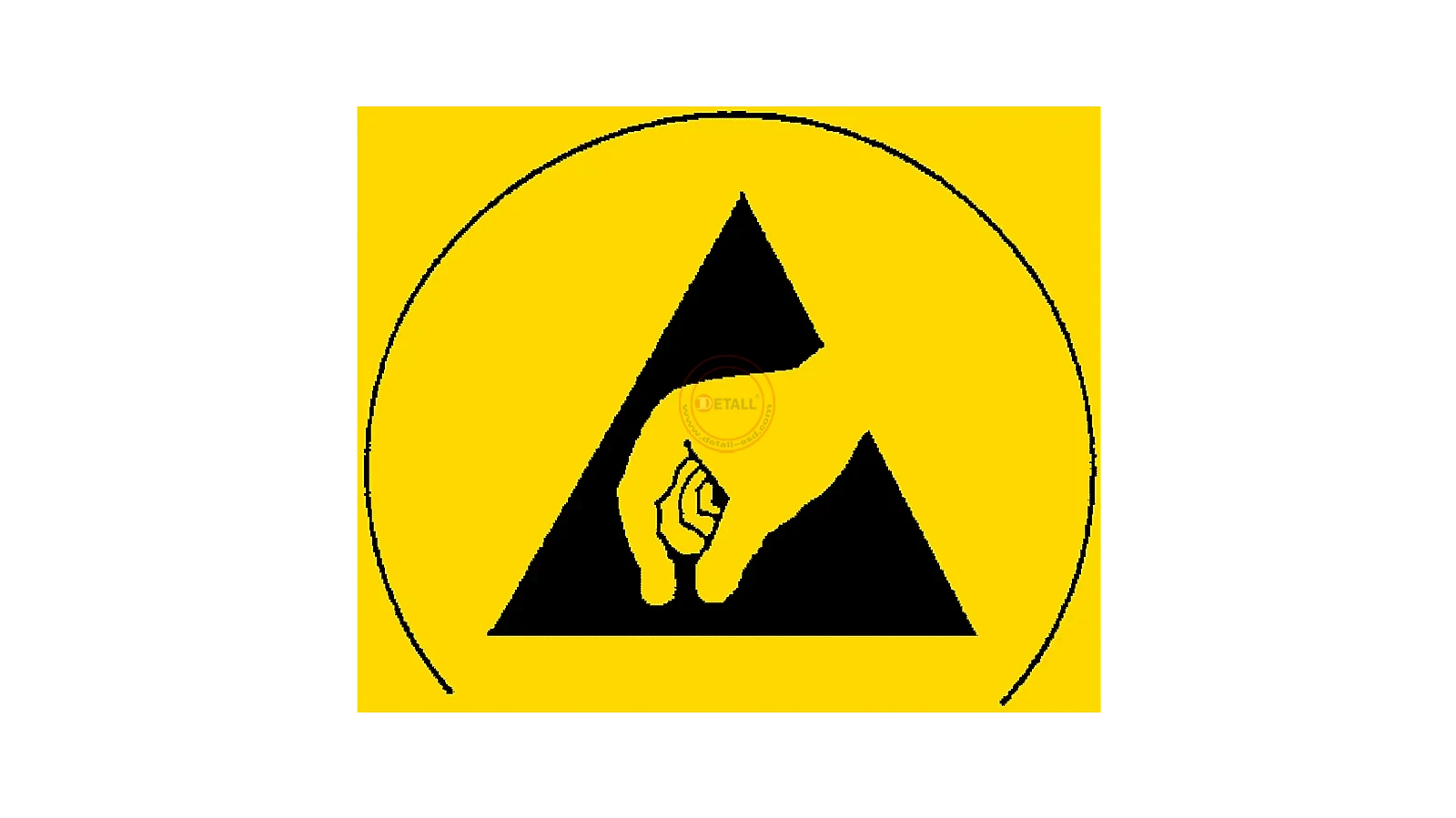

The ESD Susceptibility Symbol shows a hand in a triangle with a slash. It warns that an item is vulnerable to ESD and requires careful handling.

Symbol Design

The triangle signals caution, and the slashed hand means “do not touch.” It’s typically a yellow hand on a black background for visibility.

Applications

This symbol appears on:

- Packaging for ICs, PCBs, and other sensitive components.

- Workstations handling ESD-sensitive items.

- Labels or documentation to remind workers of precautions.

The ESD Protective Symbol: Identifying Safe Equipment

Using non-ESD-safe tools risks damage. Are you equipping your workspace correctly?

The ESD Protective Symbol features a hand in a triangle with an arc. It marks items designed to prevent ESD, like mats or clothing.

Symbol Design

The arc indicates protection, distinguishing it from the Susceptibility Symbol. It’s often yellow on black, avoiding red to prevent hazard confusion.

Applications

Found on:

- Static-shielding bags and packaging.

- ESD-safe clothing, like smocks with conductive threads.

- Equipment like wrist straps and dissipative mats.

Practical Use

Our ESD workbenches, marked with this symbol, ensure safe handling. A client reduced defects by 15% after adopting labeled protective gear.

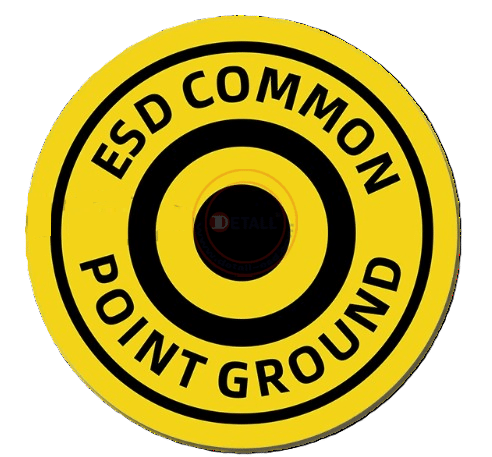

The ESD Common Point Ground Symbol: Ensuring Safe Grounding

Improper grounding can nullify ESD protection. Are your grounding points clearly marked?

The Common Point Ground Symbol is a bold circle with concentric rings and text. It indicates where grounding connections are bonded for safety.

Symbol Design

The text “ESD COMMON POINT GROUND” and circles mark grounding points. Black and white on green is common for clarity.

Applications

Used on:

- Grounding jacks or terminals on workbenches.

- Signage in ESD-protected areas (EPAs).

- Equipment requiring consistent grounding.

Grounding Importance

Every workbench in the factory displays this symbol, indicating that wrist straps and mats must be grounded. This has resulted in a 25% reduction in static-related issues.

Standards Governing ESD Symbols

Non-standard symbols cause confusion. Are you following industry guidelines?

ESD symbols are defined by standards like ANSI/ESD S8.1. These ensure consistent design and use, enhancing safety across global workspaces.

Key Standards

- ANSI/ESD S8.1: Defines symbol designs and applications (ANSI/ESD S8.1).

- IEC 61340-5-1: Guides ESD protection, including symbol use (IEC 61340-5-1).

Compliance Benefits

Compliance ensures universal recognition. Adherence to these standards within the facility has streamlined audits and enhanced safety.

Global Variations

In Europe, the Protective Symbol may include letters (e.g., “S” for shielding) per IEC 61340-5-3, adding specificity.

Best Practices for Using ESD Symbols

Misusing symbols can undermine safety. Are you applying ESD symbols correctly?

Use ESD symbols consistently with proper training. Label sensitive items, protective gear, and grounding points to maintain an effective ESD program.

Implementation Tips

- Label Clearly: Ensure symbols are visible on all relevant items.

- Train Staff: Educate workers on symbol meanings and ESD protocols.

- Audit Regularly: Check symbol placement and condition monthly.

- Integrate with EPA: Use symbols within a broader ESD control strategy.

Training Impact

Training on symbol recognition led to a 30% reduction in mishandling errors, resulting in improved product reliability.

Tools for Success

Use ESD-safe tools and signage marked with these symbols to reinforce safety protocols.

The Evolution of ESD Symbols

ESD symbols weren’t always standardized. How did they become universal?

ESD symbols evolved from industry needs in the 1970s. Pioneered by Robert F. Gabriel at Sperry Univac, they addressed rising ESD failures in electronics.

Historical Context

As transistors shrank, ESD risks grew. Gabriel’s proposal led to the Susceptibility Symbol’s adoption after global collaboration.

Modern Relevance

Today’s symbols reflect decades of refinement, ensuring clarity and effectiveness in protecting modern electronics.

Ongoing Developments

Standards continue to evolve, with updates like IEC 61340-5-3 adding functional labels for precision.

ESD Symbols Summary Table

| Symbol Name | Description | Application |

|---|---|---|

| ESD Susceptibility | Hand in triangle with slash | Marks ESD-sensitive components |

| ESD Protective | Hand in triangle with arc | Identifies ESD-safe products |

| ESD Common Point Ground | Circle with text and concentric rings | Indicates grounding points |

Conclusion

ESD symbols are vital for protecting electronics from static damage. The Susceptibility, Protective, and Common Point Ground symbols guide safe handling, equipment use, and grounding. With proper training and compliance with standards like ANSI/ESD S8.1, you can safeguard your workspace. My experience shows these symbols, when used correctly, significantly reduce costly ESD failures.

Key Citations: