ESD in Electronics Manufacturing - Why Is It So Important?

When tiny sparks cause massive problems, understanding and managing ESD becomes vital for every electronics manufacturing professional.

ESD can silently damage electronic components during production, leading to major failures, warranty costs, and product recalls if not properly controlled.

Even the smallest uncontrolled discharge can cause invisible damage to sensitive parts. Many factories underestimate ESD risks, yet they pay heavily later. Let’s explore why ESD matters so much in electronics production and how you can avoid hidden disasters.

What damage does static electricity cause to electronic components?

Invisible threats often do the most harm. Static discharge happens faster than the blink of an eye but can instantly destroy critical circuits.

Static electricity causes catastrophic or latent failures in microchips, transistors, and printed circuit boards (PCBs), leading to costly defects and quality issues.

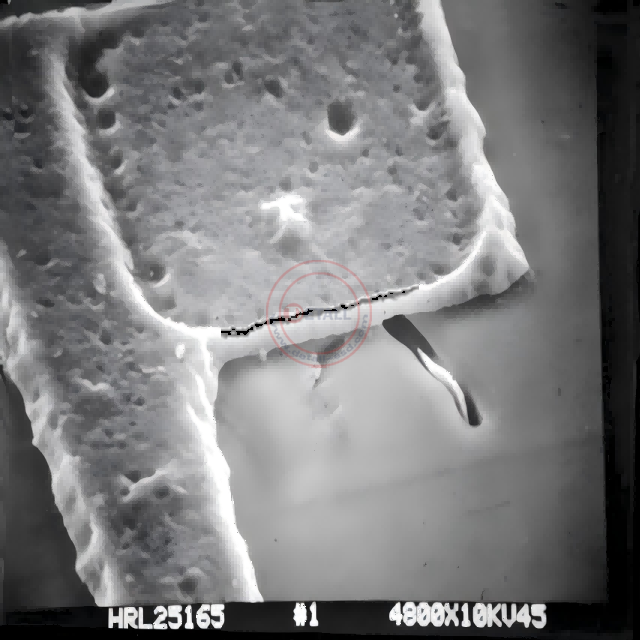

How exactly does ESD damage happen?

When a charged person or object touches an electronic component, the sudden energy transfer can:

| Failure Type | Description |

|---|---|

| Catastrophic Failure | Immediate, complete device breakdown |

| Latent Failure | Hidden weakness leading to early life failure |

| Parametric Failure | Subtle performance degradation |

Latent failures are especially dangerous because the component passes initial tests but fails later in the field, causing expensive warranty returns. Sensitive parts like MOSFETs, ICs, and memory chips are the most vulnerable.

How serious is the damage caused by ESD in electronics factories?

Many manufacturers don't realize how expensive ignoring ESD control can be until it’s too late.

Statistics show that ESD causes over 33% of all electronic component failures during production, costing billions of dollars globally each year.

The numbers behind the hidden crisis

Studies by ESD Association and other industry bodies show:

| Metric | Value |

|---|---|

| Direct loss due to ESD damage | 5% to 10% of total manufacturing cost |

| Cost of latent ESD failures | Up to 10× more than catastrophic ones |

| Percentage of PCB failures from ESD | 30% to 70% depending on process |

Factories operating without robust ESD programs often lose millions annually without even noticing the root cause.

What does ESD mean in the supply chain?

The risk doesn’t end after manufacturing. Your supply chain can become your weakest link if ESD protection is ignored.

In the supply chain, ESD refers to the potential damage that can occur during transport, handling, or storage if anti-static precautions are not properly maintained.

Where are the hidden ESD risks?

From warehouse storage to last-mile delivery, risks lurk everywhere:

| Supply Chain Stage | ESD Risk Point |

|---|---|

| Warehousing | Improper packaging or grounding |

| Transport | Handling without ESD protection bags |

| Assembly logistics | Manual picking without wrist straps |

| Customer delivery | Static buildup during shipping |

Therefore, good ESD practices must extend beyond the factory floor into every part of the journey until the final installation.

How can we prevent these problems?

If we know the dangers, we must build the defenses. Prevention always beats repair when it comes to ESD.

The best way to prevent ESD problems is by creating a fully controlled environment, including ESD-safe workstations, grounded operators, ESD-compliant materials, and continuous education.

Practical steps to build a complete ESD protection system

| Area | Measures |

|---|---|

| Workstations | Use grounded ESD workbenches and mats |

| Operators | Wear wrist straps, foot straps, ESD jackets |

| Equipment | Select ESD-certified tools and packaging |

| Environment | Control humidity and flooring conditions |

| Training and Auditing | Regularly train staff and check compliance |

From my experience, the strongest ESD control programs are the ones that combine daily discipline, good hardware, and strong awareness at every level. Cutting corners always leads to hidden costs later.

Conclusion

Understanding and preventing ESD is not optional — it is a basic responsibility in electronics manufacturing if we want quality, reliability, and long-term success.